- »

- Products »

- X-Kar »

- Superior Convection Batch Ovens »

- Bench Top Batch Ovens and Accessories »

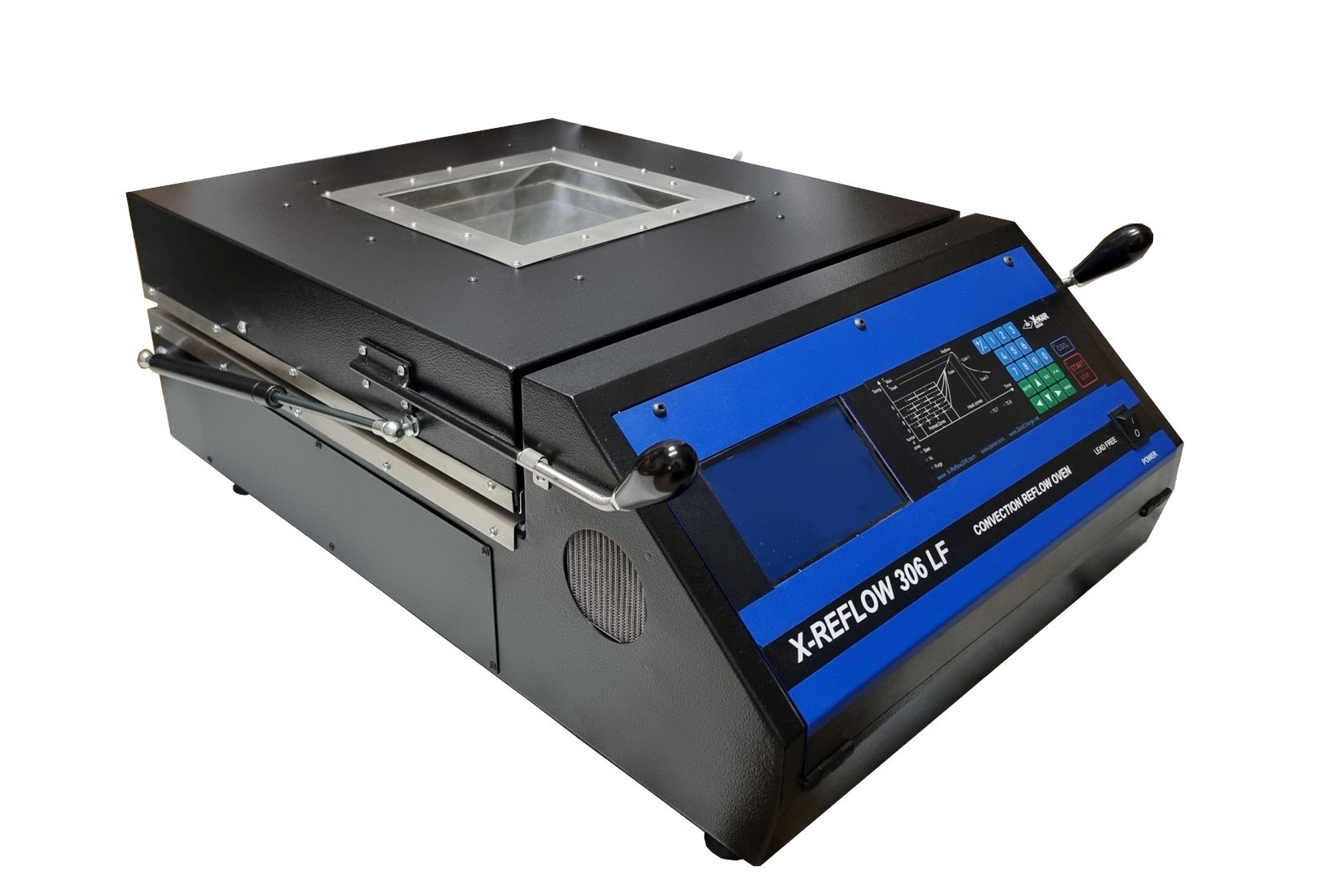

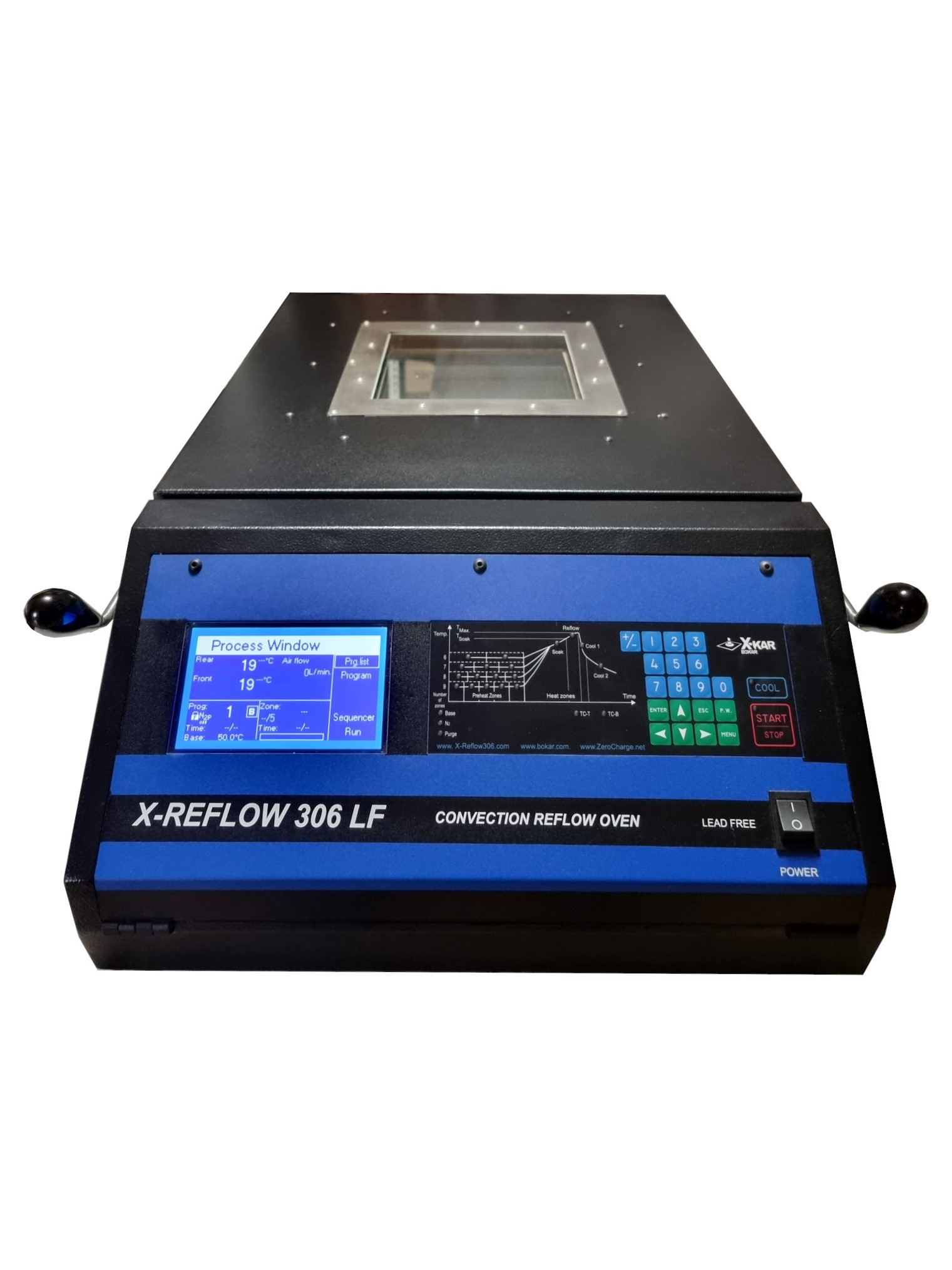

- X-Reflow-306/S One of a kind Top End Scientific Model

X-Reflow-306/S One of a kind Top End Scientific Model

It was revised in 2019 to allow control from a PC using the X-306 Oven Commander application which allowed ease of programming and very convenient control of the oven.

It was also updated to greatly increase heat rise per second and to reduce the amount of air required for the same cooling efficiency.

In addition, it is equipped with a connection to the X-O2 PPM Monitor to allow measurement of residual O2 at any time during the process.

Why X-Reflow306/S is the Best Convection Batch Oven ever built?

- This oven incorporates many features never seen before in other Batch Ovens.

- It was designed to give the operator tools needed to program and to control the heating environment and the process from start to finish with precision and accuracy from the on-board keyboard or from the PC application X-306/S Oven Commander.

- It has evolved from many years of experience and feedback from hundreds of Convection Batch Ovens users worldwide (www.BatchOven.info)

- It has all the features of the powerful and versatile five + purging zone

X-Reflow306 LF-AC model developed for the best in industry performance in Lead Free soldering (www.X-Reflow306.com) plus many unique and unmatched new features for scientific research like purity of N2 in the heating chamber or two stage fast cooling at rates of few degrees per second with choice of N2 or air (or both) , heating control based on real temperature of the heated object, and control from a PC with the X-306/S Oven Commander application. - Additional unique features which make X-Reflow306/S especially desirable for laboratories, medical equipment manufacturers and everyone else who demands the highest degree of N2 purity and precise heating and cooling process control:

- Nitrogen purity maintained in the heating chamber is 10 times better than in other batch ovens produced by other manufacturers today.

- Heating and cooling, if desired, can be controlled by the real heated object temperature (the thermocouple attached to the heated object). This means that the oven controller is not trying to maintain the preprogrammed gas temperature in the oven; instead, it is trying to maintain the pre-programmed temperature of the heated object.

- There is a choice of up to nine programmable time/temperature zones in a program plus an additional purging zone to push out oxygen when used for heating in an inert gas environment.

- An exhaust port controlled by the program to make purging 100% automatic and allow removing hot air from the oven via an exhaust pipe during the cooling zone. Hot air during the cooling process can be directed outside of the room in which the oven is located.

- Functionality to manage quantity of N2 (nitrogen) injected into the oven in three ways to maintain desired and constant nitrogen environment.

- Base Mode. In this mode the oven, after it is switched “ON” maintains a pre-programmed temperature of the air in the heating chamber. This mode can be used to start the heating process always from the same pre-programmed base temperature. When the heating/cooling program cycle is finished, the oven will ask the operator to remove the heated object. When it is removed, the oven will not cool to room temperature. It will start heating again to the pre-programmed Base Temperature so that the next heating cycle can start from the Base Temperature.

Few other manufacturers’ ovens have some of the advanced features of the

X-Reflow306/S, but none of them has all these advanced features incorporated into one compact unit.

No one can come even close to give as good nitrogen purity as the one achieved in

X-Reflow306/S and no one has computer controlled, two-stage, pre-programmed cooling media flow controller allowing repeatability and a rate of cooling in the range of a few degrees per second.

Just few examples of how these features work:

- When heating process requires an inert gas environment, the oven needs to be flushed to push out the oxygen after the oven has been closed. This is accomplished by pre-programming the flushing time and before the start of the heating cycle the entry port for nitrogen and the exhaust port for oxygen escape open simultaneously and the N2 pushes the air out of the heating chamber.

- This oven (called by some the “Laboratory Dream Oven” has nine programmable time/temperature zones + an oxygen purging zone. The number of zones (from three to nine) can be selected by an operator each time a program is created.

- The heated object (in most of the cases) needs to be heated to achieve and maintain pre-set temperature for a defined period of time called a time zone. In the ovens which control only the air temperature in the heating chamber the heaters are not supplying more heat when the air achieves the preprogrammed temperature in a particular zone, even if the heated object is at a lower than air in the heating chamber temperature. X-Reflow306/S offers a choice of control when the oven heaters will deliver heat at the optimized rate until the heated object, not the air in the heating chamber achieves the pre-programmed temperature

- The heated object often needs to be cooled to a preset temperature and at a defined period of time. X-Reflow306/S can be pre-programmed to supply exact number of SCFM (or l/min) of the cooling media in two cooling zones. Furthermore, the user can use two media’s for cooling. There is a choice of N2 in one of the cooling zones and the air in the second cooling zone.

To summarize:

It is our belief that at the present time no other manufacturer makes an equally performing convection batch oven.

X-Reflow306/S will benefit laboratories, research facilities, technical universities and the producers of unique and sophisticated low volume equipment. In short, it will help anyone who needs precise and diverse heating/cooling capabilities.

TECHNICAL SPECIFICATIONS:

|

Reflow area |

12”x12”x1.75” (305x305x45 mm) |

|

Temperature range |

30°C to 350°C |

|

Number of Zones |

Purging, to push oxygen out + variable, three to nine zones, set by the operator for each program. Last zone is a cooling zone. Max: up to 10 (ten) zones. |

|

Heaters |

2 Heaters (Front and Rear) 3kW (230V) and 3KW (208V) |

|

Max. PCB size |

12”x12” (305x305 mm) |

|

Supply Requirements |

30 amps, 230V 50/60 Hz (Max power draw: 6 kW for a few sec and 4-5 KW after that time |

|

Advanced Cooling Module Separate box connected to the oven via pneumatic and electrical lines and to the source of N2 or shop air. |

Cooling media: Nitrogen or Shop Air. Timing and object temperature to cool to is defined by the operator in the program (“K” TC must be attached to the heating object and plugged into the TC-B connector at the back of the unit). Cooling media is delivered to the oven from XMF-306 Cooling controller and enters the heating chamber through four ½” tubes in the corners of the top clamshell. Advanced cooling produces more reliable soldering connections and helps in handling heated objects after heating cycle. Opening and closure of the exhaust port is controlled by the programming. |

|

Monitoring Window Size |

7.8”x7.8” (200×200 mm) |

|

Nitrogen Connection |

1/2 “connector on XMF-306 for Purging and Cooling (4-8 bar) and standard I/M 1/4” pneumatic male plug connector for adding N2 during heating cycle (pressure:1-2bar (14.5 - 29 psi) |

|

Size |

L=30”xW=21”xH=15”-15,4” {L=765mm x W=530mm x H=380-390mm (adjustable)} |

|

Weight |

Unpacked: 100lbs. (~45 kg) Packaged for shipping: 125 Ib (57kg) |

|

Computer profile control |

Allows pre-programming, storage and recall of up to 255 programs |

|

Communication with PC |

RS485 port ( XKAR X485-USB converter required to connect to PC’s USB port) |

|

Advanced Features |

|

X-Reflow-306/S - Operating Manual

X-Reflow-306-S - Oven Commander Manual

X-O2-PPM Residual O2 Monitor Manual

XMF-306 Cooling Media Flow Controller

List of Errors displayed by Oven X-Reflow 306