P/N Stencil/Insert set

Component Information |

P/N Stencil

Component pattern |

P/N Insert |

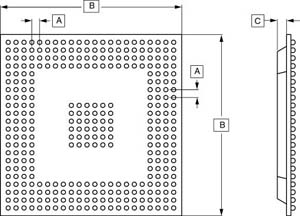

| XURB-S/I-156-1-15-1.2

Component Information

BGA156;

I/O Count 156;

Pitch 1.0mm;

Body Size 15mm;

Plastic Height 1.2mm

|

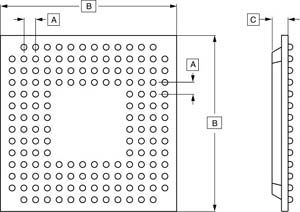

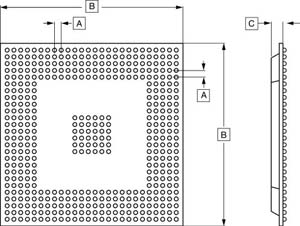

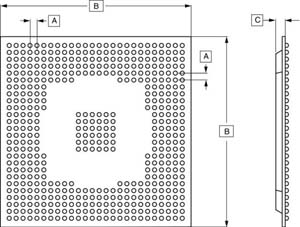

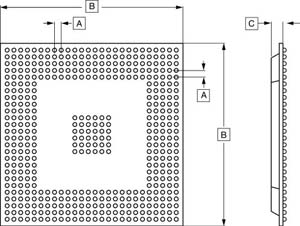

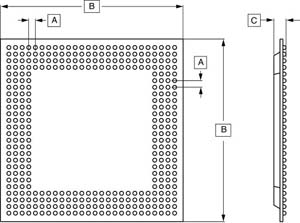

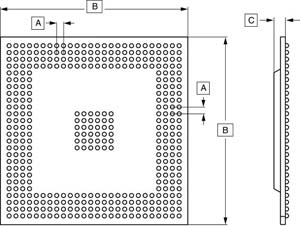

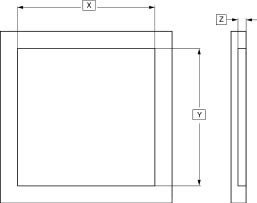

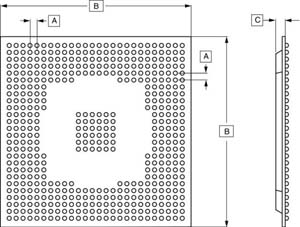

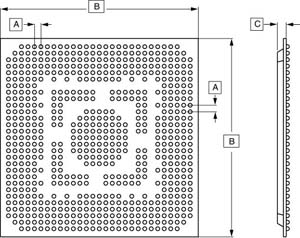

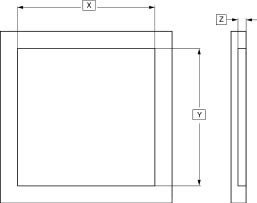

XURB-S-156-1-15

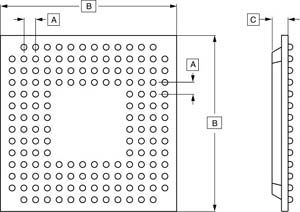

A = 1.0 mm; B = 15 mm; C = 1.2 mm |

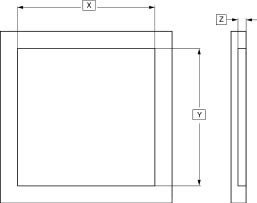

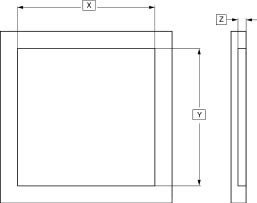

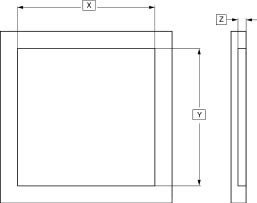

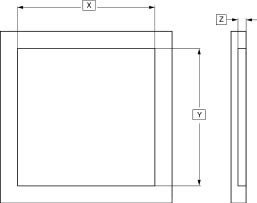

XURB-I-15-1.2

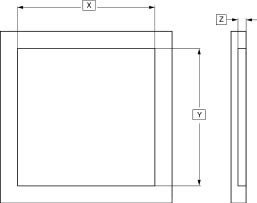

X = 15 mm; Y = 15 mm; Z = 1.2 mm |

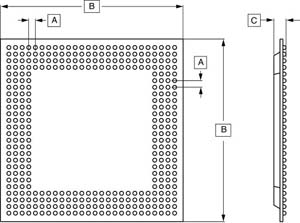

| XURB-S/I-456-1-23-1.6

Component Information

BGA456;

I/O Count 456;

Pitch 1.0mm;

Body Size 23mm;

Plastic Height 1.6mm

|

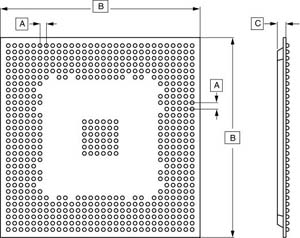

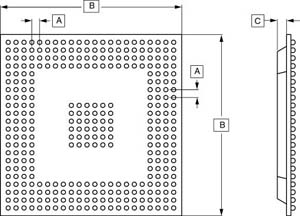

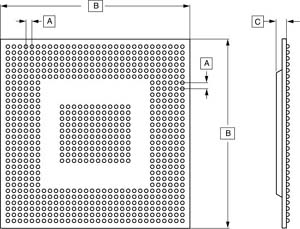

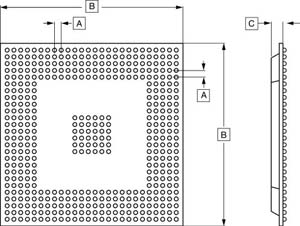

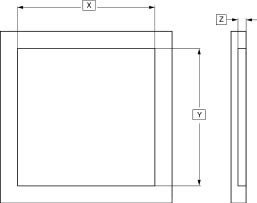

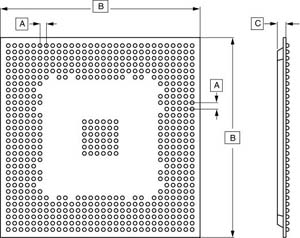

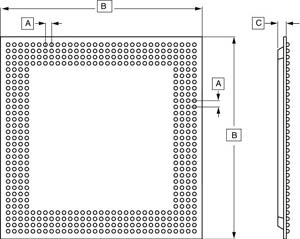

XURB-S-456-1-23

A = 1.0 mm; B = 23 mm; C = 1.6 mm |

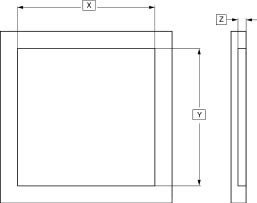

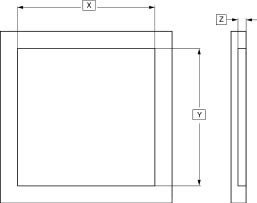

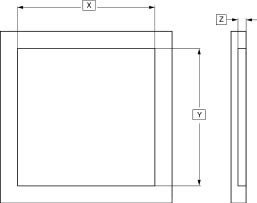

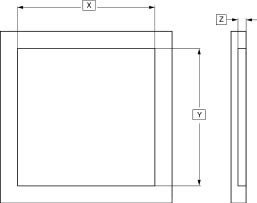

XURB-I-23-1.6

X = 23 mm; Y = 23 mm; Z = 1.6 mm |

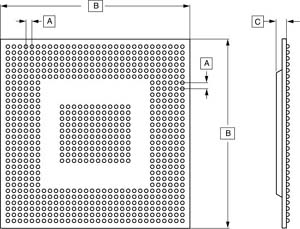

| XURB-S/I-324-1.27-27-1.6

Component Information

BGA324;

I/O Count 324;

Pitch 1.27mm;

Body Size 27mm;

Plastic Height 1.6mm

|

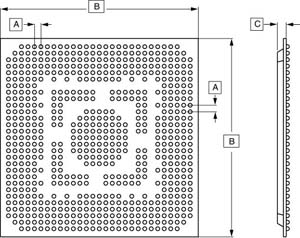

XURB-S-324-1.27-27

A = 1.27 mm; B = 27 mm; C = 1.6 mm |

XURB-I-27-1.6

X = 27 mm; Y = 27 mm; Z = 1.6 mm |

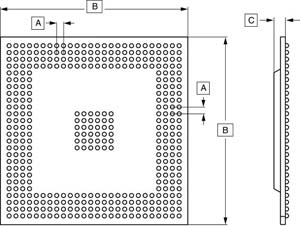

| XURB-S/I-352-1.27-27-1.6

Component Information

BGA352;

I/O Count 352;

Pitch 1.27mm;

Body Size 27mm,

Plastic Height 1.6mm

|

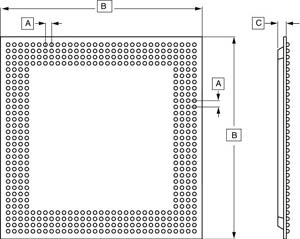

XURB-S-352-1.27-27

A = 1.27 mm; B = 27 mm; C = 1.6 mm |

XURB-I-27-1.6

X = 27 mm; Y = 27 mm; Z = 1.6 mm |

| XURB-S/I-696-1-31-1.8

Component Information

BGA696;

I/O Count 696;

Pitch 1mm;

Body Size 31mm;

Plastic Height 1.8m

|

XURB-S-696-1-31

A = 1 mm; B = 31 mm; C = 1.8 mm |

XURB-I-31-1.8

X = 31 mm; Y = 31 mm; Z = 1.8 mm |

| XURB-S/I-388-1.27-35-1.8

Component Information

BGA388;

I/O Count 388;

Pitch 1.27mm;

Body Size 35mm;

Plastic Height 1.8m

|

XURB-S-388-1.27-35

A = 1.27 mm; B = 35 mm; C = 1.8 mm |

XURB-I-35-1.8

X = 35 mm; Y = 35 mm; Z = 1.8 mm |

| XURB-S/I-456-1.27-35-1.8

Component Information

BGA456;

I/O Count 456;

Pitch 1.27mm;

Body Size 35mm;

Plastic Height 1.8m

|

XURB-S-456-1.27-35

A = 1.27 mm; B = 35 mm; C = 1.8 mm |

XURB-I-35-1.8

X = 35 mm; Y = 35 mm; Z = 1.8 mm |

| XURB-S/I-492-1.27-35-1.8

Component Information

BGA492;

I/O Count 492;

Pitch 1.27mm;

Body Size 35mm;

Plastic Height 1.8m

|

XURB-S-492-1.27-35

A = 1.27 mm; B = 35 mm; C = 1.8 mm |

XURB-I-35-1.8

X = 35 mm; Y = 35 mm; Z = 1.8 mm |

| XURB-S/I-596-1.27-35-1.8

Component Information

BGA596;

I/O Count 596;

Pitch 1.27mm;

Body Size 35mm;

Plastic Height 1.8m

|

XURB-S-596-1.27-35

A = 1.27 mm; B = 35 mm; C = 1.8 mm |

XURB-I-35-1.8

X = 35 mm; Y = 35 mm; Z = 1.8 mm |

| XURB-S/I-676-1.27-37.5-1.8

Component Information

BGA676;

I/O Count 676;

Pitch 1.27mm;

Body Size 37.5mm;

Plastic Height 1.8m

|

XURB-S-676-1.27-37.5

A = 1.27 mm; B = 37.5 mm; C = 1.8 mm |

XURB-I-37.-1.8

X = 37.5mm; Y = 37.5mm; Z = 1.8mm |

| XURB-S/I-432-1.27-40-1.6

Component Information

BGA432;

I/O Count 432;

Pitch 1.27mm;

Body Size 40mm;

Plastic Height 1.6m

|

XURB-S-432-1.27-40

A = 1.27 mm; B = 40 mm; C = 1.6 mm |

XURB-I-40-1.6

X = 40 mm; Y = 40 mm; Z = 1.6 mm |

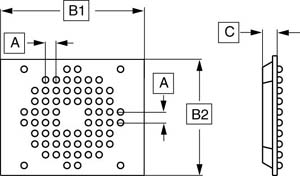

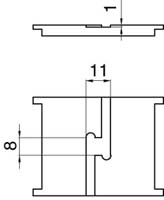

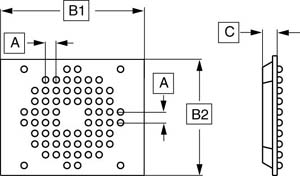

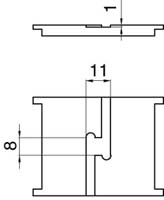

| XURB-S/I-69-0.8-11x8-1

Component Information

BGA69;

I/O Count 69;

Pitch 0.8mm;

Body Size 11x8mm;

Plastic Height 1mm

|

XURB-S-69-0.8-11x8

A = 0.8 mm; B1 = 11 mm;

B2 = 8 mm; C = 1.6 mm |

XURB-I-11x8-1

|

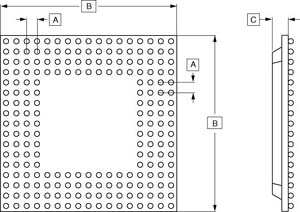

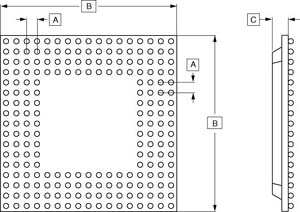

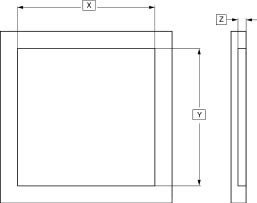

| XURB-S/I-208-0.8-15-1.2

Component Information

BGA208;

I/O Count 208;

Pitch 0.8mm;

Body Size 15mm;

Plastic Height 1.2mm

|

XURB-S-208-0.8-15

A = 0.8 mm; B = 15 mm; C = 1.2 mm |

XURB-I-15-1.2

X = 15 mm; Y = 15 mm; Z = 1.2 mm |