- »

- Products »

- X-Kar »

- SMT Assembly Equipment (Ovens, Pick and Place Machines, Stencil Printers) »

- Pick and Place Machines »

- XMP 300 Series

XMP 300 Series

Pick and Place Machines for assembly of SMT components

Our Pick and Place Machines offer the best price/performance ratio in the industry.

Features:

- The arm head is equipped with highest quality linear bearing to guarantee smooth up and down motion.

- The vacuum pump driven by a stepping motor has unmatched performance and is extremely quiet and durable.

- Precise and smooth arm movement in both X and Y axis with a possibility of adjustments.

- LED light moving with the head provides excellent long life illumination. The unique illumination system is focusing light in a work area both during a component pick-up and its placement on a board.

- Removable feeder base and loose component tray allow for preparation of components needed for a particular job ahead of time and away from the machines.

- The board holder accommodates large boards up to 15” x 12” (380 x 305 mm).

Without a carousel and XL-11 tray loader the system will accommodate boards as large as 15" x 24". - Removable feeder base and loose component tray allow for preparation of components needed for a particular job ahead of time and away from the machines.

- Quick changeover of feeders and loose components trays. Complete feeder base can be replaced by another one in seconds.

- The dispenser in XMP-302D machine offers 5 dispensing modes and storage for pre-programmed dispensing parameters for different boards or jobs.

- All sub-systems are ESD Safe and are connected in the machines to a common ESD ground point. It is fully antistatic and is supplied with AML-301A wrist strap and AS3-B ESD grounding wire.

- X-KAR XMP-300 Series models have the same identical base and the mechanism for arm movement. The machines are assembled from different modules to allow the user to buy what he/she really needs.

![]()

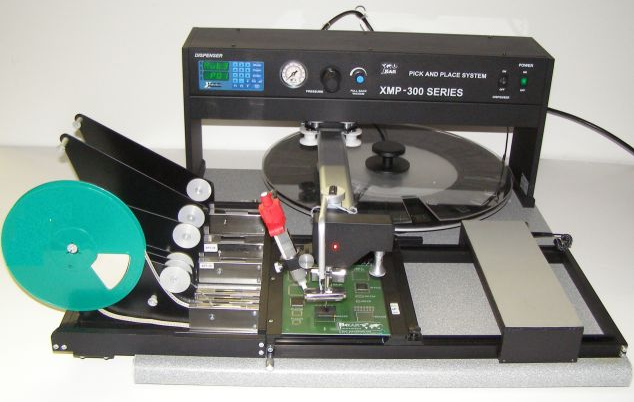

The top of the line XMP-302D Manual Pick and Place System with Digital Dispenser

Shown with XIL-1.1 Illumination System (optional)

Below there is a short description of each model starting from the simplest and the lowest cost one.

Model XMP-300 includes a common base with a board holder, loose component tray XL-11, armrest, the arm with pick and place head and a control console. The console contains a low noise vacuum pump and a circuitry allowing picking-up and releasing the component smoothly with a slight movement of a control knob.

Model XMP-301 has in addition a feeder base with six feeders (three 8 mm, one 12mm, one 16mm and one 24 mm)

Model XMP-302 has in addition to XMP-301 a console with an analog dispensing system built-in inside, and the pick-up arm equipped with a syringe holder and a syringe adapter.

Model XMP-302D is the same in function as XMP-302. The difference is only in the accuracy of a dispenser. In the model XMP-302D an analog dispenser was replaced by higher accuracy, programmable digital dispenser. The dispenser programs are very smart and will help in optimizing paste dispensing time when assembling different boards.

Note: When using a dispenser it is mandatory to use an air filter on the shop air supply line.

XIL-1.1 Illumination system provides the light at the

working point. It moves with the arm to a component

pick-up and to the component placement point on a PCB.

XFB-1 Removable Feeder Base can be moved for

a preparation for a particular job. Spare replacement

Feeder Bases are recommended for expedient assembly

XZ-AR1 - Arm rest provides the support for the arm.

It is ESD Safe and connected to common ESD ground.

It is on the rollers and moves with the arm.

XMP-300 Basic Manual Pick and Place

Machine

Introduction

Model XMP-300 includes a base with a board holder, armrest, loose component tray XL-11, pick and place arm and a control console.

![]()

Features:

- Precise and smooth arm movement in X and Y axis.

- Accommodates large boards up to 15" x 12" (380 x 305 mm).

Without an optional carousel and XL-11 tray loader the system will accommodate 15" x 24" PCB’s. - Supplied with XL-11 loose component tray with 10 trays.

- Quick changeover of loose components trays. Optional feeder base can be added and installed in seconds.

- Fully Antistatic. It is supplied with AML-301A wrist strap and AS3-B grounding wire. All subsystems are connected to a common ESD ground.

- Unique illumination system (optional) mounted on an arm and focusing light on the working area can be added to the system.

System includes:

- XMP-CC1 Control Console Assembly

- XMP-301/XMP-302 Base Assembly with Board Holder

- XNS-1 Needle/Cup set

- XZ-A301 Pick and Place Arm Assembly

- XL-11 Loose Component Tray Assembly

- XNS-1 Needle/Cup Set

- AS3-B ESD grounding wire

- AML-301A Wrist strap with coiled cord

Technical Specifications:

|

Power Source |

110-120 V or 220-240 VAC (as specified when purchasing) |

|

Air pressure (shop air) |

Max 90 psi (0,7 Mpa) |

|

Maximum placement area on the PCB |

14" x 12" (360 x 305 mm) |

|

Loose component tray loaders |

One, standard (max 2 simultaneously) |

|

Vacuum Source |

High efficiency, very quiet diaphragm pump |

|

Dimensions |

26.4" x 28.7"x 12.2" (670mm x 730mm x 310 mm) |

|

Weight |

55 lbs. (25 kg) |

|

Shipping package weight |

27.2"x 27.6" x 7.1" (690mm x 700mm x 180mm) / 36 Ib |

Optional accessories:

- XFB-1 - Feeder base

- XPT-8 - 8mm feeder

- XPT-12 - 12mm feeder

- XPT-16 - 16mm feeder

- XPT-24 - 24mm feeder

- XCAR-1 - Component Carousel

- XIL-1.1 - Illumination System

- XL-11 - Tray holder with five XL-1 single compartment and five XL-2 dual compartment trays

- XT-1/15 - Pack of 15, single compartment trays

- XT-2/15 - Pack of 15, two compartments trays

- XNS-1 - Needle/cup set (3 metal needles and 4 different sizes of ESD cups)

- XCS-1 - Cup set (2 each of 4 sizes of ESD cups)

Introduction

Model XMP-301 is a common base with a board holder, armrest, loose component tray XL-11, a feeder base and six feeders (3x8 mm, and one of each 12, 16 and 24 mm), pick and place arm and a control console.

Features:

- Precise and smooth arm movement in both X and Y axis.

- Accommodates large boards up to 15" x 12" (380 x 305 mm). Without an optional carousel and XL-11 tray loader the system will accommodate 15" x 24" PCB.

- Supplied with feeders (3x8mm and one of each, 12mm, 16mm and 24mm) and loose component tray with 10 trays.

- Quick changeover of feeders and loose components trays. Complete feeder base can be replaced by another one in seconds.

- Fully Antistatic. It is supplied with AML-301A wrist strap and AS3-B grounding wire. All subsystems are connected to a common ESD ground.

- Unique illumination system mounted on an arm is focusing light on the working area - both during pick-up of a component and the placement on a board.

- XMP-CC1 Control Console Assembly

- XMP-301/XMP-302 Base Assembly with a Board Holder

- XZ-A301 Pick and Place Arm Assembly

- XL-11 Loose Component Tray Assembly

- Six feeders (3 pcs of XPT-8, one XPT-12, one XPT-16 and one XPT-24)

- XFB-1 Feeder Base

- XNS-1 Needle/Cup Set

- AS3-B ESD grounding wire

- AML-301A Wrist strap with coiled cord

System includes:

- XMP-CC1 Control Console Assembly

- XMP-301/XMP-302 Base Assembly with a Board Holder

- XZ-A301 Pick and Place Arm Assembly

- XL-11 Loose Component Tray Assembly

- Six feeders (3 pcs of XPT-8, one XPT-12, one XPT-16 and one XPT-24)

- XFB-1 Feeder Base

- XNS-1 Needle/Cup Set

- AS3-B ESD grounding wire

- AML-301A Wrist strap with coiled cord

Technical Specifications:

|

Power Source |

110-120 V or 220-240 VAC (as specified when ordering) |

|

Air pressure (shop air) |

Max 90 psi (0,7 Mpa) |

|

Maximum placement area on the PCB |

14" x 12" (360 x 305 mm) |

|

Quantity of feeders: |

Max 20 of 8 mm feeders XPT-8 |

|

Loose component tray loaders |

One, standard (max 2 simultaneously) |

|

Vacuum Source |

High efficiency, very quiet diaphragm pump |

|

Dimensions |

26.4" x 28.7"x 12.2" (670mm x 730mm x 310 mm) |

|

Weight |

73 lbs (33 kg) |

|

Shipping package weight |

27.2"x 27.6" x 7.1" (690mm x 700mm x 180mm) / 36 Ib (18 kg) |

Optional accessories:

- XFB-1 – Feeder base

- XPT-8 - 8mm feeder

- XPT-12 - 12mm feeder

- XPT-16 - 16mm feeder

- XPT-24 - 24mm feeder

- XCAR-1 - Component Carousel

- XIL-1.1 - Illumination System

- XL-11 - Tray holder with five XL-1 single compartment and five XL-2 dual compartment trays

- XT-1/15 - Pack of 15, single compartment trays

- XT-2/15 - Pack of 15, two compartments trays

- XNS-1 - Needle/cup set (3 metal needles and 4 different sizes of ESD cups)

analog dispenser

Introduction

XMP-302 Pick, Paste and Place System was designed to allow the user to conveniently control the placement of the SMT components and the deposition of the solder paste on printed circuit boards.

![]()

Features:

- Precise and smooth arm movement in both X and Y axis.

- Accommodates large boards up to 15" x 12" (380 x 305 mm).

Without an optional carousel and XL-11 tray loader the system will accommodate 15" x 24" PCB. - Supplied with feeders (3x8mm and one of each, 12mm, 16mm and 24mm) and loose component tray with 5 single trays and 5 dual compartment trays.

- Quick changeover of feeders and loose components trays. Complete feeder base can be replaced by another one in seconds.

- Fully antistatic. It is supplied with AML-301A wrist strap and AS3-B ESD grounding wire. All subsystems are connected to a common ESD ground.

- Unique illumination system mounted on an arm is focusing light on the working area - both during pick-up of a component and the placement on a board.

- Built-in dispenser for paste of flux deposition during prototyping or assembly.

Note: When using dispenser air filter on the supply line is needed.

System includes:

- XMP-CC2 Control Console Assembly

- XMP-301/XMP-302 Base Assembly with Board Holder

- XZ-A302 Pick and Place/Dispense Arm Assembly

- XL-11 Loose Component Tray Assembly

- Six feeders (3 pcs of XPT-8, one XPT-12, one XPT-16 and one XPT-24)

- XFB-1 Feeder Base

- XDH-1 Dispensing Head Assembly

- XZ-SMA1 Syringe mounting hardware

- XFS-1 Foot Switch

- XDL-1 Compressed Air (Dispenser) connecting hose (with fitting to connect to the console)

- XNS-1 Needle/Cup Set

- AS3-B ESD grounding wire

- AML-301A Wrist strap with coiled cord

Technical Specifications:

|

Power Source |

110-120 V or 220-240 VAC (as specified when purchasing the system) |

|

Air pressure (shop air) |

Max 90 psi (0,7 Mpa) |

|

Maximum placement area on the PCB |

14" x 12" (360 x 305 mm) |

|

Quantity of feeders: |

Max 20 of 8 mm feeders XPT-8 |

|

Loose component tray loaders |

One, standard (max 2 simultaneously) |

|

Vacuum Source |

High efficiency, very quiet diaphragm pump |

|

Dimensions |

26.4" x 28.7"x 12.2" (670mm x 730mm x 310 mm) |

|

Weight |

73 lbs (33 kg) |

|

Shipping package weight |

27.2"x 27.6" x 7.1" (690mm x 700mm x 180mm) / 36 Ib (18 kg) |

Optional accessories:

- XFB-1 – Feeder base

- XPT-8 - 8mm feeder

- XPT-12 - 12mm feeder

- XPT-16 - 16mm feeder

- XPT-24 - 24mm feeder

- XCAR-1 - Component Carousel

- XIL-1.1 - Illumination System

- XL-11 - Tray holder with five XL-1 single compartment and five XL-2 dual compartment trays

- XT-1/15 - Pack of 15, single compartment trays

- XT-2/15 - Pack of 15, two compartments trays

- XNS-1 - Needle/cup set (3 metal needles and 4 different sizes of ESD cups)

XMP-302D Manual Pick and Place Machine

with Digital Dispenser

Introduction

XMP-302D Pick, Paste and Place Machine has been designed to allow the user to conveniently control the placement of SMT components and the deposition of a solder paste on printed circuit boards.

![]()

Features:

- Precise and smooth arm movement in both X and Y axis.

- Accommodates large boards up to 15" x 12" (380 x 305 mm).

Without an optional carousel and XL-11 tray loader the system will accommodate 15" x 24" PCB. - Supplied with feeders (3x8mm and one of each, 12mm, 16mm and 24mm) and loose component tray with 5 single trays and 5 dual compartment trays.

- Quick changeover of feeders and loose components trays. Complete feeder base can be replaced by another one in seconds.

- Fully antistatic. It is supplied with AML-301A wrist strap and AS3-B ESD grounding wire. All subsystems are connected to a common ESD ground.

- Unique illumination system mounted on an arm is focusing light on the working area - both during pick-up of a component and the placement on a board.

- Built-in digital dispenser for paste of flux deposition during prototyping or assembly. The dispenser offers 5 dispensing modes and storage for pre-programmed dispensing parameters for different boards or jobs. For a description of the dispenser see here. The controls and functionality of XMP-302D machine dispenser are identical.

Note: When using dispenser air filter on the supply line is needed.

System includes:

- XMP-CC3 Control Console Assembly

- XMP-301/XMP-302 Base Assembly with Board Holder

- XZ-A302 Pick and Place/Dispense Arm Assembly

- XL-11 Loose Component Tray Assembly

- Six feeders (3 pcs of XPT-8, one XPT-12, one XPT-16 and one XPT-24)

- XFB-1 Feeder Base

- XDH-1 Dispensing Head Assembly

- XZ-SMA1 Syringe mounting hardware

- XFS-1 Foot Switch

- XDL-1 Compressed Air (Dispenser) connecting hose (with fitting to connect to the console)

- XNS-1 Needle/Cup Set

- AS3-B ESD grounding wire

- AML-301A Wrist strap with a coiled cord

Technical Specifications:

|

Power Source |

110-120 V or 220-240 VAC (as specified when purchasing the system) |

|

Air pressure (shop air) |

Max 90 psi (0,7 Mpa) |

|

Maximum placement area on the PCB |

14" x 12" (360 x 305 mm) |

|

Quantity of feeders: |

Max 20 of 8 mm feeders XPT-8 |

|

Loose component tray loaders |

One, standard (max 2 simultaneously) |

|

Vacuum Source |

High efficiency, very quiet diaphragm pump |

|

Dimensions |

26.4" x 28.7"x 12.2" (670mm x 730mm x 310 mm) |

|

Weight |

73 lbs (33 kg) |

|

Shipping package weight |

27.2"x 27.6" x 7.1" (690mm x 700mm x 180mm) / 36 Ib (18 kg) |

Optional accessories:

- XFB-1 – Feeder base

- XPT-8 - 8mm feeder

- XPT-12 - 12mm feeder

- XPT-16 - 16mm feeder

- XPT-24 - 24mm feeder

- XCAR-1 - Component Carousel

- XIL-1.1 - Illumination System

- XL-11 - Tray holder with five XL-1 single compartment and five XL-2 dual compartment trays

- XT-1/15 - Pack of 15, single compartment trays

- XT-2/15 - Pack of 15, two compartments trays

- XNS-1- Needle/cup set (3 metal needles and 4 different sizes of ESD cups)