Focus X

Patented in USA, Japan and Europe.

USA Patent #: 6,761,304

The Unit offers the economical solution for sophisticated Rework.

Mature PCB Assembly and Rework industry of the new millennium requires reliable, accurate and not over priced tools for precision service and rework, which fulfill all the requirements of Process Control.

Focus "X"

Programmable SMT Rework/Repair Unit

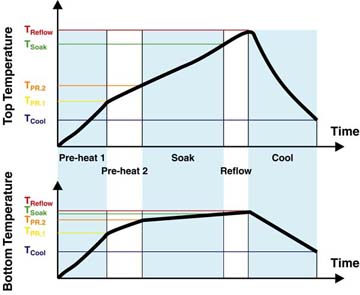

FOCUS "X", the newest system in the industry, offers total process control and best performance among convection Rework/Repair Tools. As the only system in its class can pre-program both top and bottom heating in individual zones. It is simple and easy to use. It has five time/temperature zones to accommodate lead-free solder profiling requirements (four heating and one cooling zone). When used in conjunction with X-1001 Series Prehearers or SMT-ServiCE Rework units offers 10-zone control 5 top and 5-bottom temperature settings during the rework process. For someone who really wants to bring the rework to a science, the unit has an extra mode to work in 10 zones (control the temperature rise in each of the 5 zones and maintain the reached temperature for preprogrammed period of time).

Rework of any component using FOCUS "X" is not a burden but an easy, routine repair/service task without worries that not careful or new on the job operator will damage the board during the rework process.

User programmable offset and pre-programmed bottom heating enable temperature accuracy and repeatability not found in any tools offered by other brands.

FOCUS "X" Digital SMT Convection Rework System has been designed to perform safe and efficient rework of SMD and BGA components. Microprocessor Profile Controller allows the operator to select or pre-program the appropriate removal or placement profile and start the rework sequence. Removal and placement profiles can be stored, recalled and edited with the touch of a button to guarantee process control. The profiles can be locked to eliminate operator adjustment. Programming is user friendly and can be learned in a matter of minutes.

FOCUS "X" offers 3 modes of operations: Lift Mode with 1 pre-programmed removal profile and 40 user programmable profiles, Placement Mode with 1 pre-programmed profile and 40 user programmable profiles and Hand Mode with pre-programmed maximum temperature and 40 user programmable pre-set maximum temperatures

FOCUS "X" with X-1001 Series Prehearers or SMT-ServiCE Rework units offers 10-zone control 5 top and 5-bottom temperature settings during the rework process.

FOCUS"X" can be controlled from a PC by XFR Commander Control Software.

Lift and Place Modes offer five (5) time/temperature zone control and also pre-programming of temperature settings of the bottom pre-heater in each of the 5 zones.

The system has several unique features, which makes rework more accurate, safer and consuming less of valuable time.

Features:

- Simple and cost effective nozzle design allows for duplication of the original assembly reflow profile.

- Quick Connect (twist and lock method) to attach and detach the nozzles.

- Ergonomically designed, ESD Safe and detachable for maintenance or replacement hand piece with the following advantages:

- Heater and vacuum ON-OFF Switches. Heater switch either stops or pauses the cycle. Can be pre-programmed either way from a front panel keyboard.

- Vacuum tube positioning at operator fingertips.

- Angled top to reduce cable pull during hand held operations.

- Vacuum pick-up tube and pads to lift-off the component at the end of reflow cycle.

- Allowance for storage of forty one - (1 factory set and 40 user programmable) profiles in each mode.

- Operator controlled (Hand) Mode with programmable maximum temperature.

- 3 modes of operations: Lift Mode, Placement Mode and Hand Mode. Each mode has one pre-programmed profile and 40 user-programmable profiles.

- 5 time/temperature zones for each profile PREHEAT 1, PREHEAT 2, SOAK, REFLOW and COOL DOWN + possibility to pre-program bottom pre-heat temperature in each zone.

- Foot Switch-activated Cycle Advance, to override pre-programmed zone timing.

- Operator choice of temperature scale (Celsius or Fahrenheit).

- Locking Function to protect against unauthorized parameters change.

- User accessible offset adjustment for a particular nozzle to obtain extremely accurate display of hot air temperature at the end of selected nozzle. The offset is remembered for every profile individually.

- The Unit was designed to offer the best price/performance ratio in the industry for the system capable to handle sophisticated Rework.

- "K" TC input for temperature measurements with external thermocouple to allow the user to perform temperature verification at any time during the rework process.

- Auto Lift trigger connector to activate XK-AL Series tool holders with Auto Lift Mechanism, which lifts the component automatically at the end of reflow cycle.

FOCUS "X" is the only system in the industry today giving pre-programming of the bottom pre-heat in each zone. Such powerful functions may be found only in systems with price tag far exceeding 25.000.00 USD.

System includes:

- FOCUS "X" - Basic Unit

- XHT-15 - Hot Air Tool

- XTH-2 - Tool Holder for XHT Series

- XQF - Quick Connect for easy attachment of nozzles

- XVCS-5 - Vacuum Cup Set (5 vacuum cups, 3 sizes)

- XT-1 - Vacuum Cup placement/removal tool

- XNR-2 - Hot Nozzle Handling Cup

- XFS-1 - Foot Switch

- XK-TC30/36 - "K" Type Thermocouple, gauge 30, lengths 36"

| Focus "X" comes in 3 different configurations: |

- Focus "X" -- Hand piece connections at the front.

- Focus "X1" -- Hand piece connections at the back.

- Focus "X2" -- Hand piece connections are included on the front and on the back panels. Customer can connect the hand piece on either side

Technical Specyfications

| Input Voltages | 110-120, 220-240V AC |

|---|---|

| Power Consumption | 750 W |

| Fuse | 8A for 110-120V or 5A for 220-240V Slow-Blow 5mm x 20mm |

| Heater | Resistive, 710W line voltage |

| Heater Control | PID, Closed-Loop Thermocouple sensor feedback |

| Air Source | High efficiency diaphragm pump |

| Air Flow | Variable, 3 - 20 l/min, air flow controlled by the valve located on the front panel |

| Vacuum source | Diaphragm pump |

| Vacuum | 200mmHg (8" Hg) |

| Temperature | 70 ºC - 450 ºC (158 ºF - 842 ºF)(8" Hg) |

| Weight | 10kg (22 lbs) |

| System dimensions | 150mm x 220mm x 220mm (5.9" x 8.7" x 8.7") |

| Packaged weight | 12kg (26 lbs) |